Introduction

In the modern power industry, the reliability of high voltage switchgear is paramount. Yet, one of the most insidious threats to electrical infrastructure remains largely invisible until catastrophic failure occurs: partial discharge (PD). Traditional maintenance approaches rely on periodic manual inspections, leaving critical vulnerabilities undetected between service intervals. Today, advanced online monitoring systems are revolutionizing how utilities and industrial facilities protect their assets through real-time partial discharge detection.

This comprehensive guide explores the technology, benefits, and implementation strategies for high voltage cabinet partial discharge online monitoring systems—a critical solution for transitioning from reactive to predictive maintenance.

The Hidden Threat: Understanding Partial Discharge in High Voltage Equipment

Partial discharge occurs when electrical stress causes localized breakdown of insulation material within high voltage equipment. Unlike complete electrical breakdown, partial discharge represents a gradual degradation process that can persist for months or years before manifesting as catastrophic failure.

Common causes of partial discharge include:

- Insulation material aging and degradation

- Manufacturing defects or voids in insulation

- Contamination from moisture, dust, or conductive particles

- Mechanical stress and thermal cycling

- Electrical overstress from transient voltages

The danger lies in the silent progression of these faults. A high voltage switchgear cabinet may appear to operate normally while internal insulation deteriorates, until suddenly—without warning—complete failure occurs, resulting in unplanned outages, equipment damage, and potentially catastrophic consequences for industrial operations.

The cost of failure is staggering. A single unplanned power outage can cost industrial facilities millions of dollars in lost production, equipment damage, and operational disruption. For critical infrastructure like hospitals, data centers, and manufacturing plants, the consequences extend beyond financial loss to include safety risks and service disruptions.

The Limitations of Traditional Maintenance Approaches

Conventional high voltage equipment maintenance relies on periodic manual inspections conducted by trained technicians. While these inspections are essential, they have inherent limitations:

1. Limited Frequency Manual inspections typically occur weekly or monthly, leaving extended periods during which faults can develop undetected. Critical degradation can progress rapidly between inspection intervals.

2. Incomplete Coverage Technicians cannot simultaneously monitor all equipment across a facility. Larger installations may have dozens or hundreds of switchgear units, making comprehensive coverage impractical.

3. Reactive Rather Than Predictive Traditional approaches identify problems only after they have progressed to detectable levels. By this point, significant insulation damage may have already occurred, reducing the window for planned corrective action.

4. Operator Dependency The quality of inspections depends heavily on technician experience, training, and attentiveness. Human factors introduce variability and potential for oversight.

5. Inability to Predict Failure Progression Without continuous data collection, maintenance teams cannot establish trends or predict when equipment will reach critical failure thresholds, making it impossible to schedule maintenance proactively.

The Solution: Advanced Online Partial Discharge Monitoring

Modern online monitoring systems address these limitations through continuous, multi-dimensional detection and intelligent analysis. These systems employ three complementary sensing technologies that work together to provide comprehensive partial discharge detection:

1. TEV (Transient Earth Voltage) Monitoring

TEV sensors detect transient voltage pulses induced on the metal cabinet surface during partial discharge events. This non-contact measurement technique offers several advantages:

- Easy Installation: Sensors mount externally on cabinet surfaces without requiring internal modifications

- Cost-Effective: Minimal hardware requirements compared to other detection methods

- Reliable in Most Environments: Effective for detecting PD in typical switchgear installations

TEV monitoring is particularly valuable for detecting faults within metal-enclosed switchgear and detecting corona discharge on conductor surfaces.

2. UHF (Ultra-High Frequency) Detection

UHF sensors capture electromagnetic signals in the 300 MHz to 1.5 GHz frequency range generated by partial discharge events. This technology provides distinct advantages:

- Superior Noise Immunity: High-frequency signals are less susceptible to industrial electromagnetic interference

- Precise Localization: UHF signals enable accurate identification of fault locations within equipment

- Early Detection Capability: Sensitive to incipient faults that may not yet produce detectable TEV signals

UHF monitoring excels in electromagnetically noisy industrial environments and provides the highest specificity for PD source localization.

3. Acoustic Emission (AE) Monitoring

AE sensors detect ultrasonic sound waves generated by partial discharge events. This technology offers unique benefits:

- Extreme Sensitivity: Capable of detecting very early-stage discharge events

- Specific Fault Detection: Particularly sensitive to creeping discharge and surface discharge phenomena

- Independent of Electrical Characteristics: Acoustic signals are unaffected by electrical noise or grounding conditions

Acoustic emission monitoring provides early warning capability that complements electrical detection methods.

The Power of Multi-Dimensional Analysis

By combining these three detection technologies, modern monitoring systems achieve comprehensive fault detection that surpasses any single method. Data fusion algorithms correlate signals from all three modalities, enabling:

- Confirmation and Validation: Multiple independent signals confirm the presence of actual PD events, reducing false alarms

- Fault Characterization: Different PD types produce characteristic signatures across all three detection methods, enabling precise fault classification

- Trend Analysis: Continuous data collection enables statistical analysis of PD activity over time, revealing degradation trends

- Predictive Modeling: Machine learning algorithms trained on historical data can predict equipment failure risk and remaining useful life

System Architecture and Implementation

A comprehensive online partial discharge monitoring system consists of several integrated components:

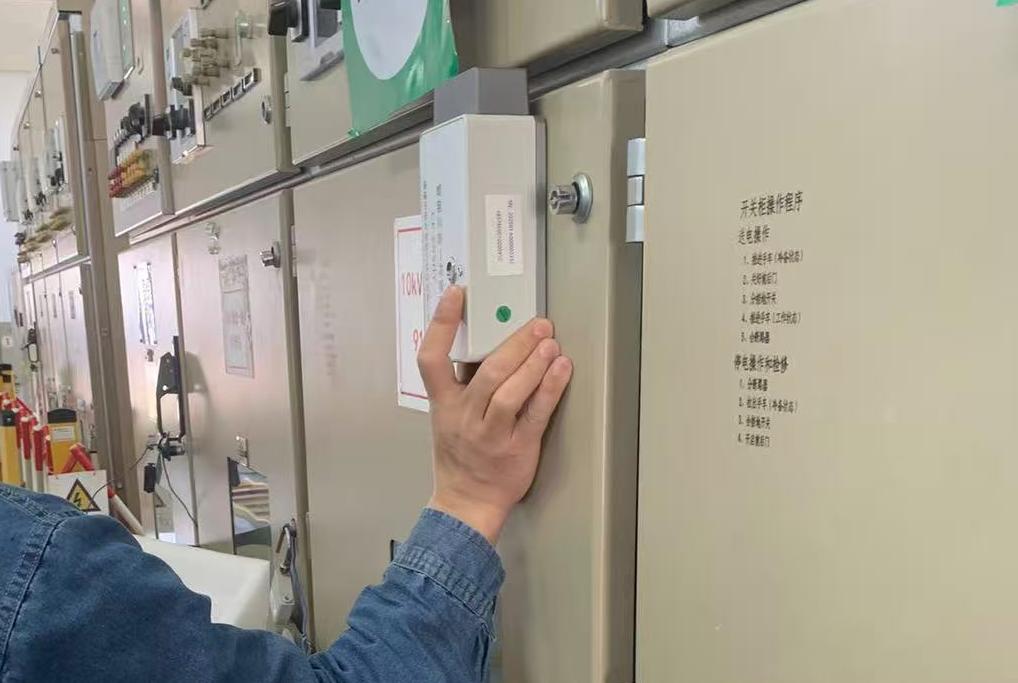

Sensor Layer Strategically positioned sensors on switchgear cabinets continuously acquire PD signals. Modern systems employ wireless sensor networks to minimize installation complexity and cost.

Data Acquisition and Processing Edge computing devices perform initial signal processing, feature extraction, and preliminary analysis. This distributed approach reduces bandwidth requirements and enables local alerting.

Cloud-Based Analytics Platform Processed data is securely transmitted to cloud infrastructure where advanced analytics engines perform:

- Real-time signal analysis and PD event detection

- Trend analysis and statistical modeling

- Predictive analytics using machine learning algorithms

- Integration with facility management systems

User Interface and Alerting Intuitive dashboards provide real-time equipment status, historical trends, and predictive insights. Automated alerting systems notify maintenance teams of concerning developments, enabling proactive intervention.

Key Benefits and Performance Metrics

Organizations implementing advanced online partial discharge monitoring systems report significant improvements:

Reliability Improvement

- Unplanned Outage Reduction: 95% reduction in unplanned outages caused by switchgear failures

- Equipment Availability: Increased equipment uptime through planned maintenance scheduling

- System Resilience: Enhanced ability to maintain critical operations during maintenance windows

Cost Optimization

- Maintenance Cost Reduction: 40% reduction in overall maintenance expenditures through elimination of unnecessary inspections and emergency repairs

- Operational Efficiency: Reduced emergency response requirements and associated labor costs

- Asset Life Extension: 30% increase in switchgear operational life through optimized maintenance timing

Operational Advantages

- Predictive Scheduling: Maintenance can be planned during convenient windows rather than responding to failures

- Reduced Emergency Response: Fewer crisis situations requiring expensive emergency repairs

- Data-Driven Decision Making: Objective, quantitative basis for maintenance decisions replaces subjective judgment

Safety Enhancement

- Hazard Prevention: Early detection prevents catastrophic failures that could endanger personnel

- Compliance Support: Demonstrates proactive approach to equipment reliability and regulatory compliance

- Risk Mitigation: Reduces probability of cascading failures affecting other systems

Industry Standards and Regulatory Framework

The adoption of online partial discharge monitoring is supported by established industry standards and regulatory guidance:

DL/T 1498 Standard (China) This national standard specifies requirements for partial discharge monitoring devices for high voltage equipment. Compliance with this standard ensures equipment meets rigorous performance and reliability criteria.

IEC 60270 Standard (International) International standard for partial discharge measurement techniques provides globally recognized methodology for PD detection and analysis.

IEEE Standards IEEE 1415 and related standards provide guidance on high voltage equipment maintenance and condition assessment, supporting the transition to predictive maintenance approaches.

These standards validate the technical approach and provide confidence in system performance and reliability.

Real-World Application Cases

Case Study 1: Large Industrial Manufacturing Facility

A major manufacturing facility with 150+ high voltage switchgear units experienced recurring unplanned outages averaging 12 per year, each costing approximately $500,000 in lost production. After implementing online partial discharge monitoring:

- Unplanned outages reduced to 0.6 per year (95% reduction)

- Maintenance costs decreased 40% through elimination of unnecessary inspections

- Equipment reliability improved significantly, enabling just-in-time maintenance scheduling

- System investment recovered within 18 months through cost savings and outage prevention

Case Study 2: Regional Power Distribution Utility

A utility serving 500,000+ customers implemented online monitoring across 200+ substations. Results included:

- Prevented 47 potential failures in first year of operation

- Reduced emergency service calls by 60%

- Improved customer satisfaction through enhanced service reliability

- Enabled transition to condition-based maintenance replacing time-based schedules

Case Study 3: Data Center Operations

A hyperscale data center operator deployed online monitoring to protect critical power infrastructure:

- Achieved “five-nines” (99.999%) availability target through proactive fault prevention

- Eliminated unplanned downtime events that could affect thousands of customers

- Reduced maintenance costs while improving system reliability

- Provided competitive advantage through superior infrastructure reliability

Implementation Best Practices

Successful deployment of online partial discharge monitoring requires careful planning and execution:

1. Comprehensive System Assessment

- Evaluate current equipment inventory and condition

- Identify critical assets where monitoring provides maximum value

- Assess existing infrastructure for integration with monitoring systems

2. Technology Selection

- Evaluate vendor solutions based on technical capabilities, reliability, and support

- Consider multi-technology approaches that combine TEV, UHF, and acoustic monitoring

- Ensure systems support integration with existing facility management infrastructure

3. Phased Deployment

- Begin with pilot installations on critical equipment

- Establish baseline data and validate system performance

- Gradually expand to broader equipment portfolio

4. Personnel Training

- Ensure maintenance teams understand system capabilities and limitations

- Develop procedures for responding to system alerts

- Establish protocols for data analysis and decision-making

5. Data Management and Analysis

- Establish secure data storage and access controls

- Develop analytical procedures for trend identification

- Create decision frameworks for maintenance scheduling based on monitoring data

6. Continuous Improvement

- Monitor system performance and refine alert thresholds

- Analyze false alarm rates and optimize detection algorithms

- Regularly review maintenance decisions and outcomes

Future Trends and Emerging Technologies

The field of online equipment monitoring continues to evolve with emerging technologies and methodologies:

Edge Computing and AI Increasingly sophisticated algorithms deployed at edge devices enable local decision-making and reduce dependence on cloud connectivity. Machine learning models continuously improve through exposure to diverse equipment and operating conditions.

Digital Twin Technology Virtual representations of physical equipment enable simulation and optimization of maintenance strategies before implementation. Digital twins can predict equipment behavior under various scenarios and identify optimal maintenance timing.

IoT Integration Seamless integration with broader industrial IoT ecosystems enables correlation of equipment condition with operational parameters, environmental factors, and maintenance history. This holistic approach provides deeper insights into equipment reliability drivers.

Autonomous Maintenance Systems Future systems may autonomously execute corrective actions—such as adjusting operational parameters or isolating faulty equipment—based on monitoring data and predictive analysis.

Blockchain-Based Verification Distributed ledger technology could provide tamper-proof records of equipment condition history and maintenance actions, enhancing transparency and accountability.

Conclusion: From Reactive to Predictive Maintenance

The transition from reactive to predictive maintenance represents a fundamental shift in how organizations approach equipment reliability. Online partial discharge monitoring systems enable this transformation by providing continuous, objective data about equipment condition and degradation trends.

The benefits are substantial and well-documented:

- Dramatic reduction in unplanned outages

- Significant cost savings through optimized maintenance

- Enhanced safety and regulatory compliance

- Extended equipment operational life

For any organization operating high voltage equipment—whether utilities, industrial facilities, data centers, or critical infrastructure operators—online partial discharge monitoring represents a strategic investment in reliability, safety, and operational efficiency.

The technology is mature, proven, and increasingly recognized as industry best practice. Organizations that embrace this approach today will gain competitive advantages through superior reliability and operational efficiency, while those that delay risk falling behind in an increasingly competitive landscape.

The future of power system reliability is predictive, data-driven, and intelligent. Online partial discharge monitoring is a critical enabler of this future.