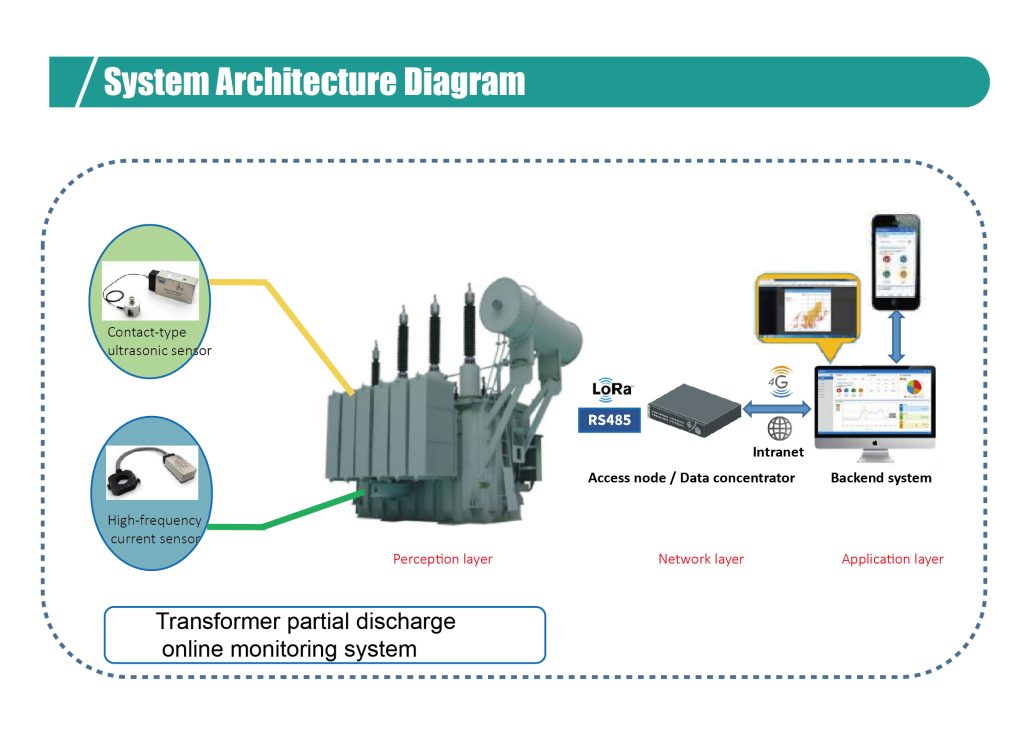

System Architecture

The Transformer PD Online Monitoring System is designed to continuously monitor and assess the insulation condition of transformers using advanced sensors and data acquisition technologies. It integrates high-frequency current and ultrasonic detection with wireless and wired communication for real-time data analysis.

System Functions

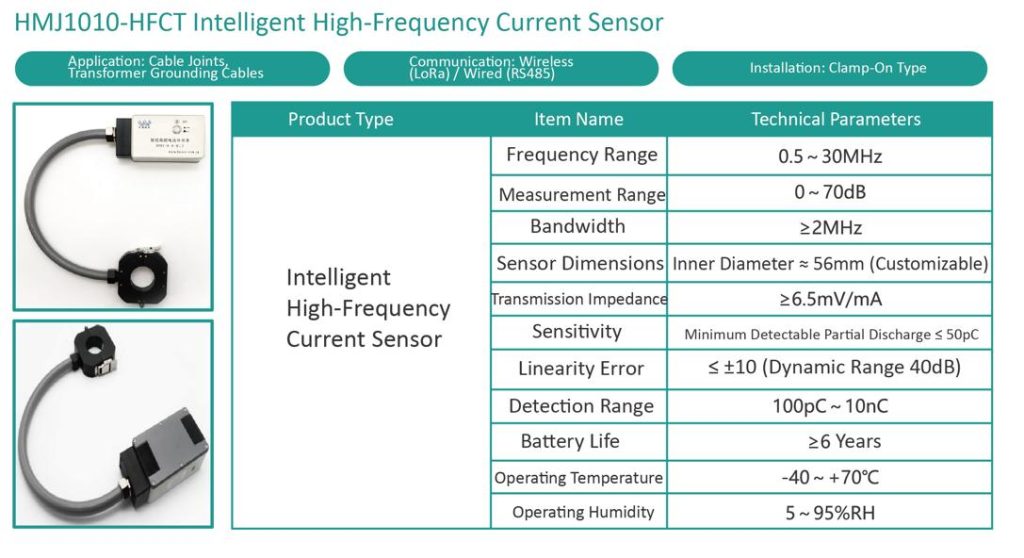

Intelligent High-Frequency Current Sensors (HFCT):

Monitor partial discharges in the main transformer based on the pulse current principle. The HFCT sensor is clamped onto the transformer grounding line to detect high-frequency pulse current signals generated by PD, providing detailed information on the insulation condition of the monitored equipment.

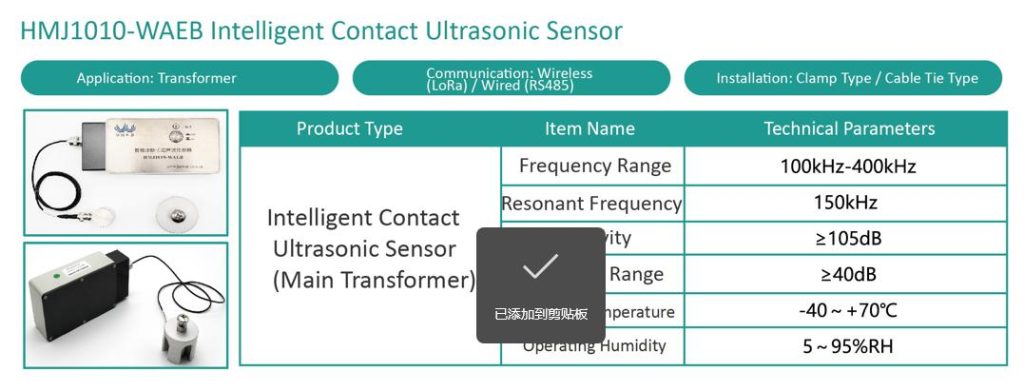

Intelligent Contact Ultrasonic Sensors (WAEB):

Measure partial discharges inside the transformer by detecting ultrasonic signals on the oil tank’s outer wall and converting them into electrical signals for analysis.

Data Transmission:

The intelligent sensors transmit collected PD signals via LoRa wireless communication to access nodes. The access nodes then forward the data to the backend server through 4G wireless or wired Ethernet connections.

System Features

Safe and Reliable:

The integrated monitoring devices do not affect transformer integrity or normal operation. They can continuously or periodically monitor, record, and reflect the operating status and characteristic parameters of the equipment accurately and reliably.

Flexible and Efficient:

Sensor configuration can be adapted based on equipment operating conditions and risk levels. Key components can be monitored precisely, providing comprehensive condition assessment and early warning.

Standardized:

The system establishes a unified framework for transformer condition monitoring, analysis, diagnostics, early warning, and communication standards.

Field Deployment Applications

The system can be flexibly deployed in substations and transformer rooms for continuous condition monitoring and preventive maintenance, enhancing transformer safety and reliability.