Background and Challenges

In the critical infrastructure of power grids, substation equipment—including transformers, switchgear, and cables—is constantly under operational stress. Over time, insulation can degrade due to aging, mechanical forces, or environmental factors, leading to the development of partial discharge (PD). If left undetected, this minor electrical discharge can escalate, causing severe insulation breakdown and catastrophic equipment failure. Such failures not only compromise the safety and stability of the power grid but also result in costly, unplanned outages.

A Proactive Solution: The Online PD Monitoring System

To address these challenges, advanced online partial discharge monitoring systems offer a proactive approach to asset management.

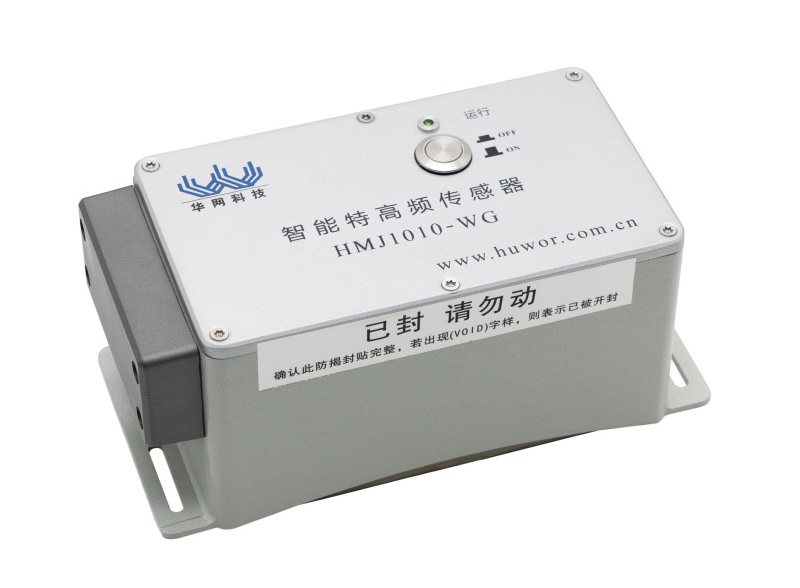

1. High-Frequency (UHF) Sensing Technology

The system deploys highly sensitive Ultra-High Frequency (UHF) sensors to capture the electromagnetic wave signals emitted by PD in real time. These sensors are specifically designed to have a high signal-to-noise ratio, enabling them to effectively differentiate between internal PD signals and external environmental noise, ensuring accurate data collection.

2. Real-Time Data Acquisition and Intelligent Analysis

Data from the sensors is transmitted to a central data concentrator, which then uploads the information to a sophisticated backend platform (e.g., a PMS or a dedicated monitoring system). The system’s intelligent algorithms automatically analyze the data, identifying the type of discharge, assessing its severity, and tracking its development trends.

3. Smart Alerting and Predictive Insights

The backend system is configured to automatically generate alerts for abnormal discharge activity, notifying maintenance crews of high-risk equipment. By comparing real-time data with historical trends, the system provides valuable insights into the equipment’s health status, enabling a shift from reactive, time-based maintenance to a more efficient, condition-based strategy.

Key Benefits of Implementation

Deploying an online PD monitoring system delivers significant and tangible results:

- Reduced Failure Rates: Early detection of PD prevents sudden, unexpected equipment failures, enhancing overall system safety.

- Extended Asset Lifespan: Proactive identification and mitigation of insulation issues reduce irreversible damage, maximizing the operational life of valuable assets.

- Optimized Maintenance Costs: The transition to a “condition-based” maintenance model eliminates unnecessary inspections and reduces the need for costly unscheduled repairs.

- Enhanced Grid Reliability: By ensuring the health and stability of key substation assets, the system significantly improves the reliability of the entire power grid, minimizing unplanned power outages.