Our latest partial discharge (PD) online monitoring project for a substation has successfully completed all stages of production, functional testing, and quality inspection. The entire system—consisting of high-frequency current sensors, ultrasonic PD sensors, IED concentrators, and accompanying accessories—has now entered the shipment phase and will soon arrive on site for installation.

Strict Quality Control to Ensure Long-Term Reliability

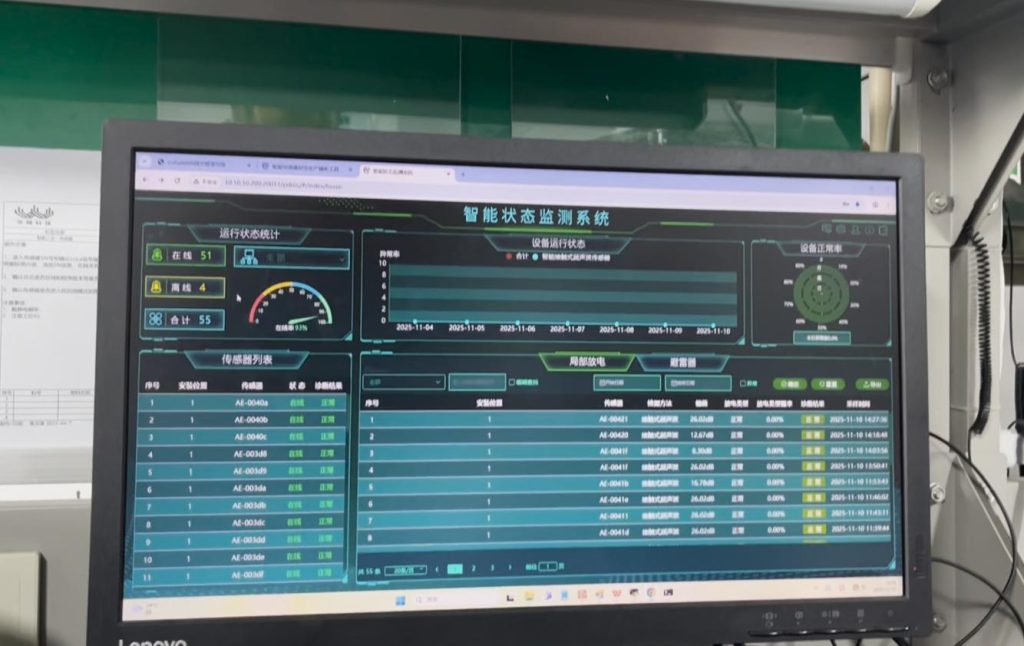

This project adopts a mature PD online monitoring solution that utilizes multi-channel sensing technologies—mainly high-frequency current detection and ultrasonic detection—to continuously track the insulation condition of substation equipment. The system provides long-term operational data to support predictive maintenance and reduce equipment risks.

All core components follow standardized manufacturing procedures. Before leaving the factory, the full system undergoes a comprehensive performance verification process:

- High-frequency current sensors are tested individually for sensitivity, bandwidth, and signal consistency.

- Ultrasonic PD sensors pass a series of responsiveness and stability checks.

- IED concentrators are tested for data acquisition speed, communication reliability, and remote transmission performance.

Each device has its own inspection report and certificate to ensure full traceability.

System-Level Commissioning Before Shipment

To guarantee smooth installation at the site, the entire monitoring system undergoes a pre-delivery configuration process, including:

- Channel integrity check

- Real-time monitoring validation

- Software interface and communication tests

- Parameter configuration and joint debugging

All units have passed the final quality review and meet the delivery requirements.

Secure Packaging and On-Time Shipment

To ensure safe transportation, the equipment is packaged with reinforced materials, anti-shock protection, and clear labeling. After final inspection, all items were sealed and collected by the logistics provider for delivery according to the project schedule.

Committed to Providing Reliable PD Monitoring Solutions

Partial discharge online monitoring is a key tool in maintaining the health of substation equipment. By continuously tracking PD activity and insulation trends, operators can identify early-stage defects, prevent failures, and improve system reliability.

The successful shipment of this project reflects the customer’s trust in our technology and product quality. We will continue to develop reliable PD monitoring and live-line detection solutions, contributing to safer and smarter power systems.