Partial discharge in transformers does not occur randomly. In most cases, it is the result of specific insulation weaknesses or installation-related issues that develop over time. Understanding what causes partial discharge in transformer systems is the first step toward preventing insulation failure and unplanned outages.

Rather than focusing on test values alone, identifying the root causes of partial discharge helps engineers make better maintenance and design decisions.

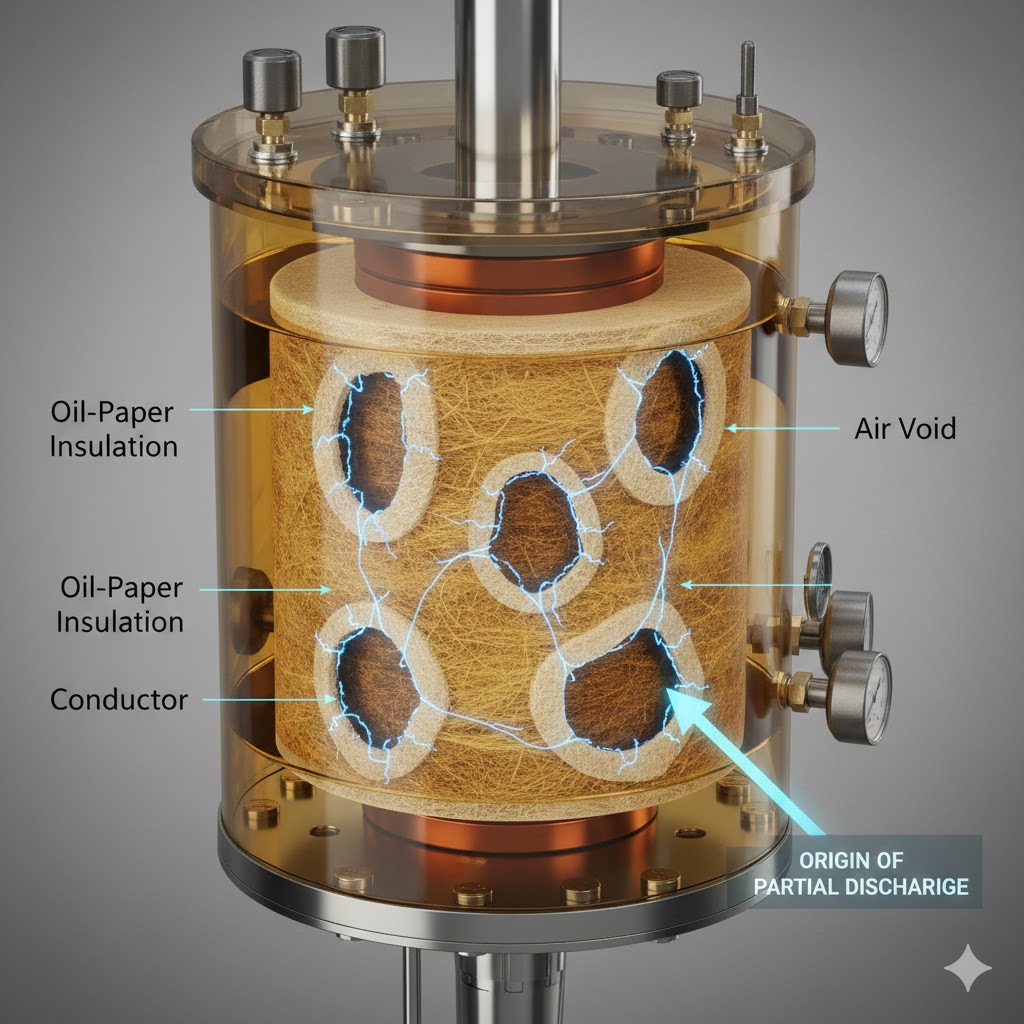

Insulation Voids and Manufacturing Defects

One of the most common answers to what causes partial discharge in transformer is the presence of microscopic voids within solid insulation materials. These voids may be introduced during manufacturing or develop later due to thermal and mechanical stress.

Under operating voltage, electric fields concentrate inside these voids, initiating partial discharge activity even when the overall insulation appears intact.

Aging and Thermal Degradation of Insulation

Transformer insulation ages continuously under electrical, thermal, and chemical stress. Over time, oil-paper insulation loses its mechanical strength and dielectric properties. Elevated operating temperatures accelerate this process, increasing the likelihood of discharge inception.

In many aging transformers, partial discharge becomes more active during load peaks, clearly indicating insulation deterioration.

Moisture Contamination in Oil-Paper Insulation

Moisture is another critical factor when analyzing what causes partial discharge in transformer insulation systems. Water reduces dielectric strength and promotes localized electric field distortion.

Even a small increase in moisture content can significantly raise partial discharge activity, especially in paper insulation layers near high-voltage conductors.

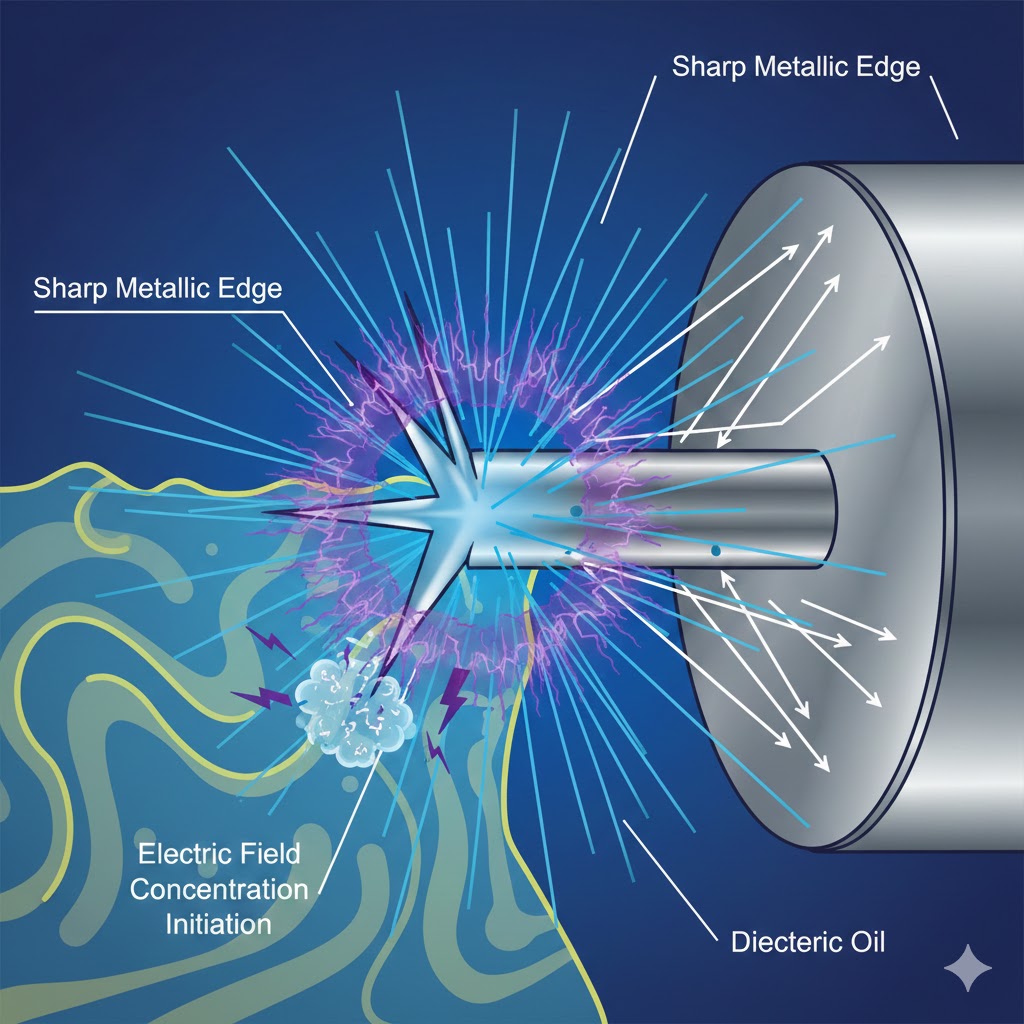

Sharp Edges and Improper Electric Field Distribution

Poorly designed or damaged internal components can create sharp edges and irregular electric field distribution. These local stress points often trigger partial discharge at relatively low voltage levels.

Such defects may result from manufacturing tolerances, mechanical displacement during transportation, or long-term vibration during operation.

Floating Potentials and Loose Connections

Floating conductive parts and loose internal connections are often overlooked causes of partial discharge. When components are not properly grounded, voltage differences can develop unpredictably, creating conditions favorable for discharge activity.

This type of partial discharge is particularly dangerous because it can intensify rapidly and may not follow gradual aging patterns.

Oil Degradation and Gas Bubble Formation

Transformer oil degradation leads to the formation of gas bubbles, especially under high electrical stress. Gas bubbles have much lower dielectric strength than oil, making them ideal sites for partial discharge initiation.

In severe cases, continuous discharge inside gas bubbles can escalate into more serious insulation breakdown.

Conclusion

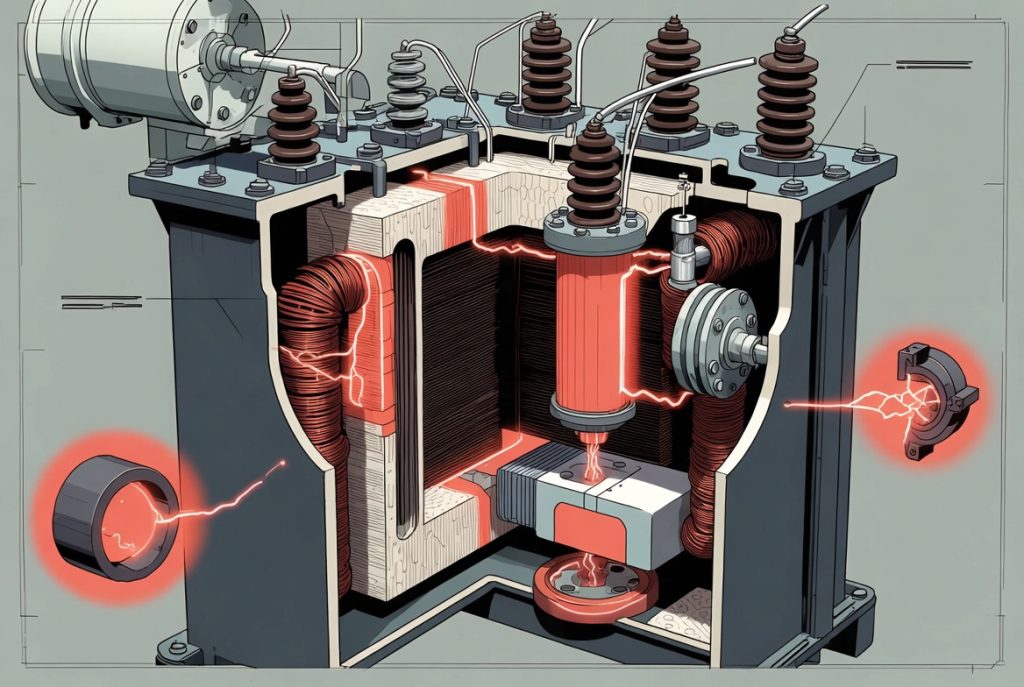

When asking what causes partial discharge in transformer systems, the answer is rarely a single factor. In practice, partial discharge usually results from a combination of insulation defects, aging, contamination, and design or installation issues.

By understanding these causes, engineers can focus on prevention, improve insulation design, and apply appropriate monitoring techniques to detect problems before they lead to failure.