Introduction

Partial discharge in transformer insulation is one of the earliest indicators of internal electrical deterioration. Although it may not cause immediate failure, partial discharge (PD) gradually weakens insulation strength and significantly increases the risk of unexpected transformer outages.

For utilities and industrial operators, understanding how partial discharge forms, how it affects transformer reliability, and how it can be detected in practice is essential for effective condition-based maintenance.

What Is Partial Discharge in a Transformer?

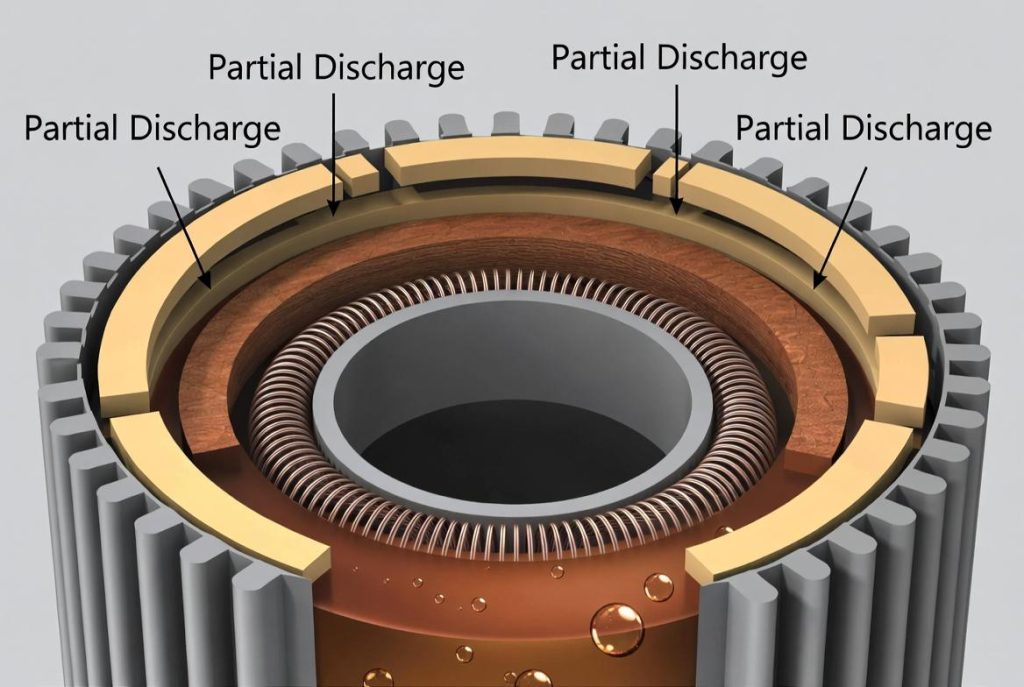

Partial discharge refers to a localized electrical discharge that only partially bridges the insulation between conductors. In transformers, PD typically occurs in areas where the electric field is intensified due to insulation defects or aging.

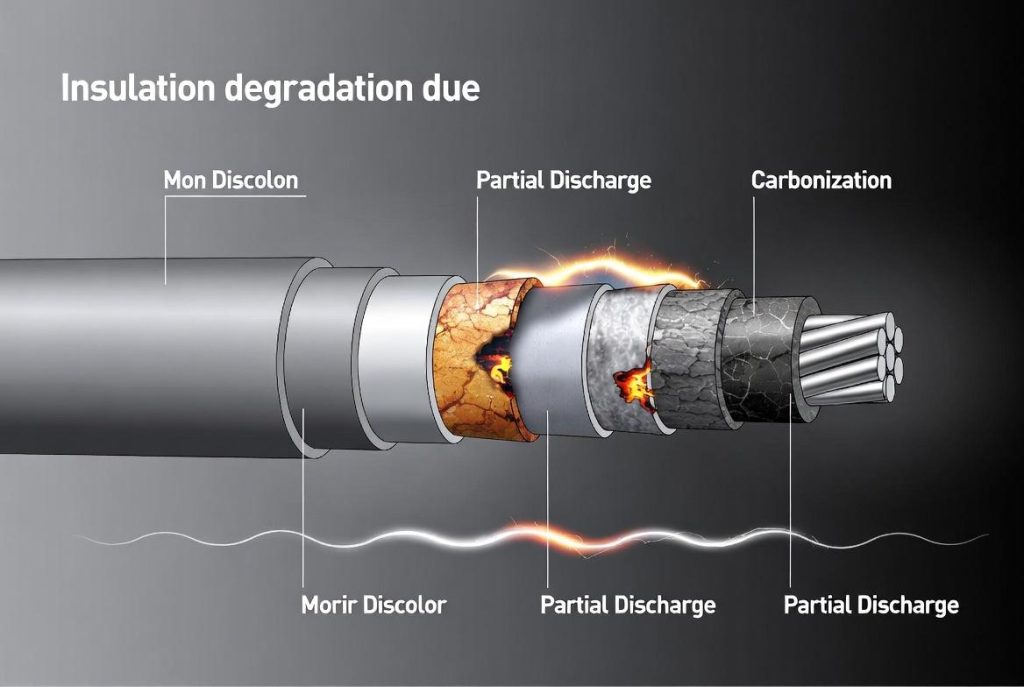

Unlike complete breakdown, partial discharge does not immediately short-circuit the transformer. However, each discharge event releases energy that erodes insulation materials over time.

Common Locations of Partial Discharge

- Voids or air gaps inside solid insulation

- Oil-paper insulation interfaces

- Sharp edges or protrusions on conductors

- Floating metal parts inside the transformer

Main Causes of Partial Discharge in Transformers

Partial discharge in transformers usually results from a combination of electrical, mechanical, and environmental factors rather than a single cause.

1. Insulation Aging

Thermal stress, oxidation, and moisture gradually reduce the dielectric strength of oil and paper insulation, creating favorable conditions for PD.

2. Manufacturing Defects

Small voids, poor impregnation, or misaligned insulation introduced during production can become PD sources under operating voltage.

3. Mechanical Stress and Vibration

Short-circuit forces or long-term vibration may loosen windings, forming micro-gaps that trigger discharge activity.

4. Overvoltage Conditions

Lightning impulses or switching surges can significantly raise electric field intensity, accelerating partial discharge development.

Why Partial Discharge Is Dangerous for Transformers

Although partial discharge energy is relatively small, its cumulative effect is destructive.

- Continuous PD causes chemical decomposition of insulation materials

- Discharge activity generates gas, heat, and acoustic signals

- Insulation erosion increases the probability of catastrophic failure

How Partial Discharge in Transformers Is Detected

Detecting partial discharge requires specialized techniques that can capture electrical, acoustic, or electromagnetic signals produced during discharge events.

Electrical Detection (IEC 60270 Method)

This traditional method measures apparent charge and is widely used in factory acceptance tests and laboratory environments.

Acoustic Emission Detection

PD activity generates ultrasonic waves that propagate through transformer oil and tank walls. Acoustic sensors can locate the discharge source without de-energizing the transformer.

Ultra-High Frequency (UHF) Method

UHF sensors detect electromagnetic signals emitted by PD, offering strong noise immunity and suitability for on-line monitoring.

Dissolved Gas Analysis (DGA)

While not a direct PD measurement, gas patterns such as hydrogen and acetylene can indicate discharge-related insulation degradation.

On-line vs Off-line Partial Discharge Testing

| Testing Mode | Characteristics | Typical Applications |

| On-line PD Testing | Performed during normal operation | Condition monitoring, early warning |

| Off-line PD Testing | Transformer de-energized | Commissioning, fault investigation |

For critical assets, on-line partial discharge monitoring provides continuous insight without interrupting service.

Best Practices for Managing Partial Discharge in Transformers

- Establish baseline PD data during commissioning

- Combine PD testing with DGA and thermal monitoring

- Track PD trends rather than relying on single measurements

- Investigate sudden PD level changes immediately

A structured monitoring strategy allows operators to intervene before partial discharge evolves into irreversible insulation failure.

Conclusion

Partial discharge in transformers is not merely a test result—it is a clear signal of insulation stress and future risk. By understanding its causes, recognizing its long-term impact, and applying appropriate detection techniques, asset owners can significantly extend transformer service life and reduce unplanned outages.

Early detection and informed maintenance decisions remain the most effective defense against transformer insulation failure caused by partial discharge.