Introduction: The Silent Threat to Electrical Integrity

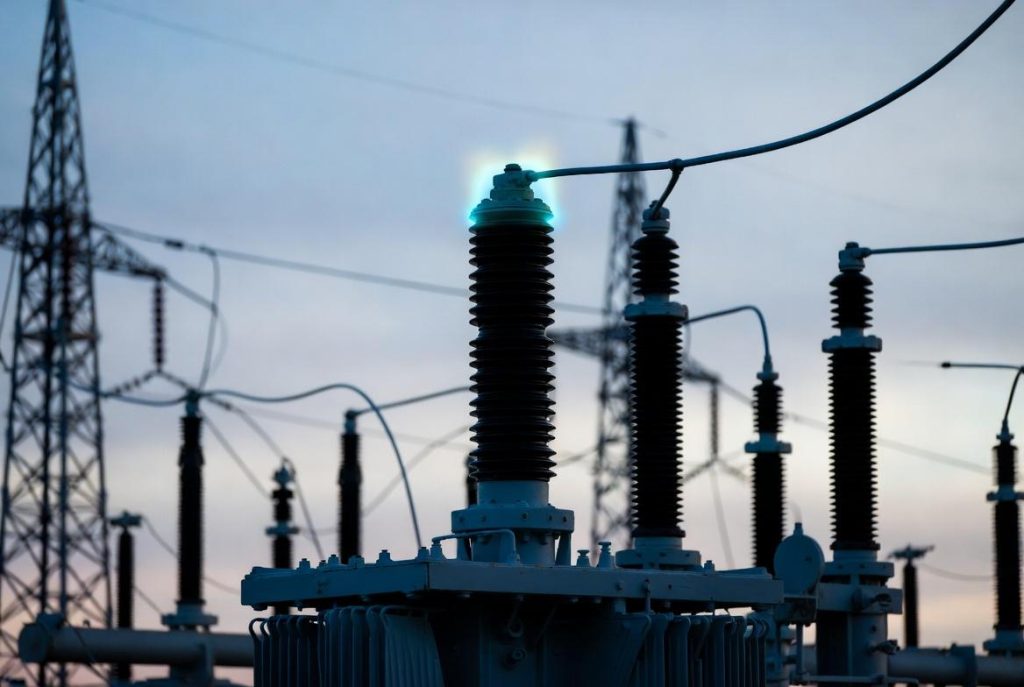

In the world of high-voltage (HV) electrical infrastructure, longevity and reliability hinge entirely on the integrity of the insulation system. Yet, deep within cables, switchgear, and transformers, a subtle, often undetectable form of degradation is taking place: Partial Discharge (PD).

PD is not a complete failure, but rather a localized electrical discharge that only partially bridges the insulation between two conductors. While minute in energy, these repeated discharges erode the dielectric material over time, creating a path for eventual, catastrophic dielectric breakdown. Understanding and accurately measuring PD is, therefore, the cornerstone of modern, effective electrical asset management and predictive maintenance.

1. Defining Partial Discharge: The Physics Behind the Phenomenon

What Exactly is PD?

Partial Discharge is best described as a short-lived, localized electrical discharge occurring within a specific, small region of a solid or liquid electrical insulation system under high voltage stress.

This phenomenon requires a local weak spot in the insulation (a void, crack, or inclusion) where the local electric field strength, E, exceeds the dielectric strength of the material within that small space. When this happens, the gas trapped in the void ionizes and a brief current pulse occurs—this is the PD event.

The Four Primary Types of PD

The characteristics of PD change significantly based on where they originate. PD is generally categorized into four main types:

- Internal Discharges (Voids): Occurring within solid insulation (like in cables or bushings) due to trapped gas voids. This is the most damaging type.

- Surface Discharges: Tracking along the surface of the insulation, often starting at interfaces between different materials, usually caused by contamination or moisture.

- Corona Discharges: Occurring in gas (like air) around sharp conductor points, primarily at the conductor-gas interface. Common on overhead lines but can be indicative of a serious issue in enclosed equipment.

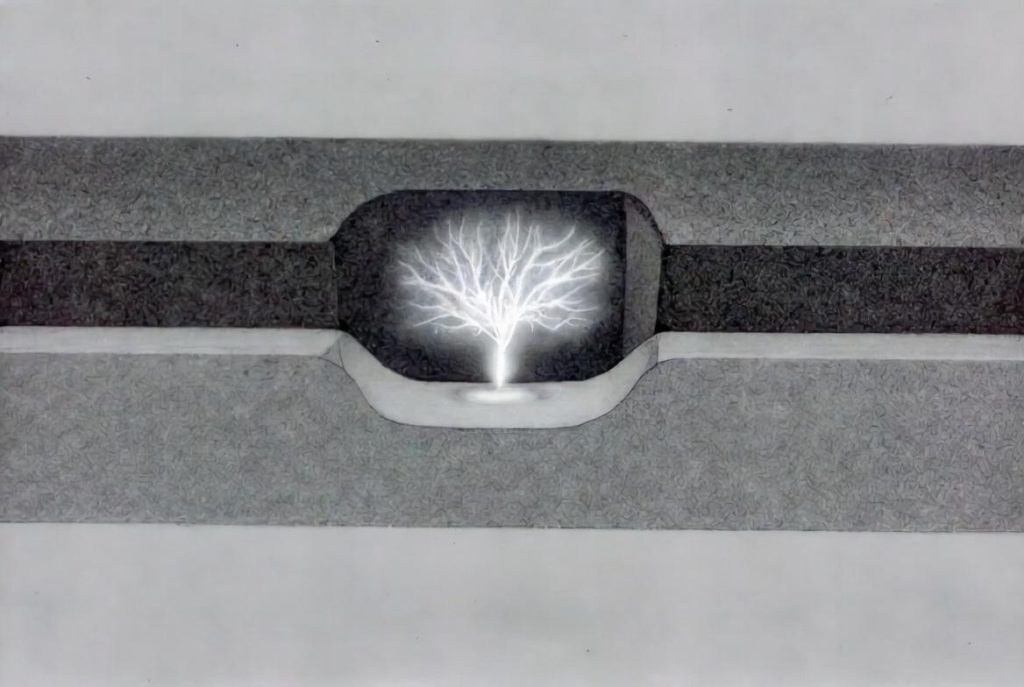

- Treeing: A pattern of damage that literally resembles a tree branch, caused by the continuous erosion from PD, leading to a breakdown channel.

2. The Destructive Mechanism: Why PD Must Be Monitored ��

PD is a slow killer of electrical equipment. Each discharge releases small amounts of energy in the form of light, sound (acoustic), heat, and chemical decomposition (like ozone and nitrogen oxides). The cumulative effect is severe:

- Erosion: The high-energy electrons impact the void surfaces, slowly pitting and eroding the insulation.

- Chemical Degradation: The energy breaks down surrounding compounds, often leading to the formation of conductive carbonized paths.

- Thermal Stress: Localized heating exacerbates the aging process of the dielectric material.

Over months or years, these discharges convert the insulation’s weak spot into a conductive path, ultimately leading to a complete and devastating flashover or equipment explosion.

3. Advanced PD Testing: From Prevention to Predictive Maintenance

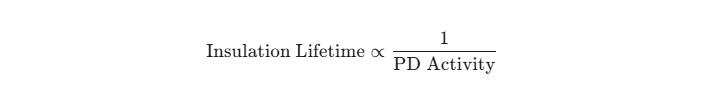

The goal of PD testing is not just to detect discharge, but to localize, characterize, and trend its activity before failure is imminent. Modern PD testing is central to Condition Monitoring (CM).

Common Measurement Techniques

- High-Frequency Current Transformer (HFCT) / Capacitive Coupling: Directly measuring the fast current pulses generated by PD. Excellent for online monitoring of cable systems.

- Acoustic Emission (AE) Testing: Using specialized sensors (often mounted externally) to detect the ultrasonic sound waves generated by PD inside a transformer or switchgear.

- Transient Earth Voltage (TEV) Testing: Measuring the tiny voltage transients that escape from the metal enclosure of switchgear, making it a very effective and non-invasive screening tool.

- Ultra-High Frequency (UHF) Testing: Best for gas-insulated switchgear (GIS) and power transformers. The UHF signals are less attenuated by the equipment structure, allowing for precise localization.

By trending the Magnitude (pC – picoCoulombs) and the Phase-Resolved Partial Discharge (PRPD) pattern, engineers can diagnose the specific type of defect and estimate the remaining equipment lifespan.

Conclusion: Securing the Future of Electrical Infrastructure

In an era where power system reliability is non-negotiable, the proactive management of Partial Discharge has transitioned from an optional check to an essential pillar of maintenance strategy. By leveraging sophisticated PD monitoring tools, asset managers can move away from time-based maintenance towards a predictive approach, extending asset life, minimizing unscheduled outages, and ensuring the safety and operational continuity of critical electric