In the world of high-voltage electrical infrastructure, reliability is not just a preference—it is a necessity. The failure of a single critical asset, such as a transformer or switchgear, can lead to catastrophic downtime, significant financial loss, and severe safety hazards. While routine maintenance is essential, it often fails to detect the subtle, internal deterioration that precedes major failure. This is where the partial discharge tester (PD tester) steps in, transforming maintenance from a reactive chore into a precise, predictive science.

What is Partial Discharge? The “Silent Killer”

Partial Discharge (PD) is a localized dielectric breakdown of a small portion of a solid or fluid electrical insulation system under high-voltage stress. It is a subtle, yet relentless, process that occurs within the insulation, not across the entire gap between conductors. These minute electrical sparks are often referred to as the “silent killer” because they are invisible to the naked eye and can continue for years, slowly eroding the insulation material until a complete, catastrophic failure occurs .

PD activity generates a range of detectable phenomena:

- Electrical Pulses: High-frequency current pulses.

- Acoustic Emissions: Ultrasonic and audible noise.

- Electromagnetic Waves: Radio frequency (RF) and ultra-high frequency (UHF) signals.

- Light and Heat: Minor localized heating and light emission.

A partial discharge tester is a specialized instrument designed to detect, measure, and analyze these signals, providing an early warning system for insulation degradation.

The Strategic Benefits of Integrating PD Testers into Your Workflow

Moving beyond traditional time-based maintenance schedules, integrating PD testing into a condition-based monitoring strategy offers profound advantages:

1. True Predictive Maintenance

Unlike simple insulation resistance tests, PD testing provides a direct, quantitative measure of insulation health. By tracking the magnitude and pattern of PD over time, maintenance teams can accurately predict the remaining life of an asset and schedule repairs or replacements precisely when needed, minimizing unnecessary downtime and maximizing asset utilization.

2. Enhanced Safety and Reliability

PD is a precursor to flashover and complete insulation failure. By identifying and localizing PD sources early, operators can mitigate the risk of sudden equipment failure, which is often accompanied by explosions or fires, thereby significantly improving personnel safety and overall system reliability.

3. Optimized Capital Expenditure

Replacing high-voltage assets like large transformers or gas-insulated switchgear (GIS) is immensely costly. PD testing allows asset managers to justify capital expenditure with hard data, proving that an asset is truly at risk before committing to a multi-million dollar replacement. Conversely, it can also confirm that older assets are still healthy, extending their service life safely.

Choosing the Right Partial Discharge Tester: Critical Features

The market offers a variety of PD testers, from laboratory-grade systems to portable field instruments. Selecting the right equipment depends heavily on the application. Key features to consider include:

| Feature | Importance | Description |

| Sensitivity & Precision | High | The ability to detect PD signals as low as a few picocoulombs (pC), crucial for early detection. |

| Noise Suppression | High | Essential for field testing, as the tester must distinguish true PD signals from environmental noise (e.g., radio, corona, power electronics). |

| Portability & Connectivity | Medium to High | Handheld or portable units are necessary for on-site testing. Modern testers often include wireless connectivity for data transfer and remote analysis. |

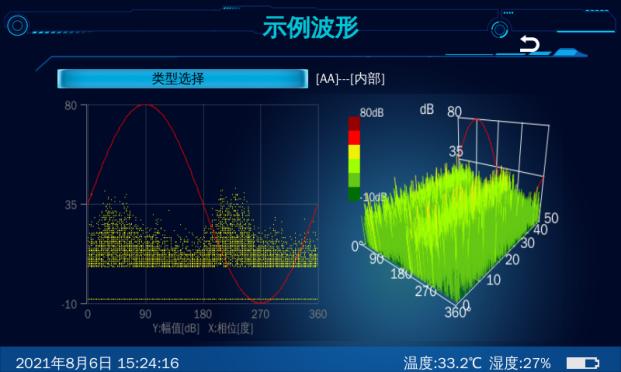

| Analysis Software | High | The software must be capable of generating Phase-Resolved Partial Discharge (PRPD) patterns to help diagnose the type of defect (e.g., void, surface discharge, corona). |

Visualizing the Threat: PRPD Patterns

A critical function of advanced PD testers is the generation of Phase-Resolved Partial Discharge (PRPD) patterns. These plots map the PD activity against the power cycle, creating unique signatures that allow experienced analysts to identify the root cause of the discharge, such as internal voids, floating electrodes, or surface tracking.

Industry Applications: Where PD Testing Matters Most

The application of the partial discharge tester spans nearly every sector that relies on high-voltage electrical power.

| Industry Sector | Typical Assets Tested | PD Testing Benefit |

| Power Generation | Generators, Stator Windings, Bushings | Prevents catastrophic failure in critical rotating machinery. |

| Transmission & Distribution | Power Transformers, Switchgear, GIS, Cables | Ensures grid stability and prevents widespread outages. |

| Industrial Plants | High-Voltage Motors, Drives, Substations | Protects continuous manufacturing processes from unexpected shutdown. |

| Renewable Energy | Wind Turbine Generators, Solar Inverter Stations | Essential for remote monitoring and maintenance of distributed assets. |

The rise of online and continuous monitoring systems, often utilizing permanently installed sensors and handheld PD testers, has made condition assessment more accessible and less intrusive than ever before.

Conclusion: Investing in Insight, Not Just Equipment

The partial discharge tester is more than just a piece of diagnostic equipment; it is an investment in operational insight. By providing a window into the otherwise hidden degradation of electrical insulation, it empowers engineers and maintenance professionals to make data-driven decisions that extend asset life, prevent costly failures, and uphold the highest standards of safety. As electrical grids become more complex and the demand for uninterrupted power grows, the role of the PD tester will only become more central to the future of reliable power asset management.